Ball Valve -Three Piece (15mm to 50mm)

Technical Specifications : Manufacturing Std. : BS 5351 / EN ISO 17292-2004 Face to Face , End to End : Manufacturers Standard

End Connections : Screwed Ends B1.20.1 Socket Weld Ends to

B1. 20.1 /EN ISO 17292-2004

Inspection and Testing Std : BS6755 (Part 1)/ EN ISO 12266

MOC:

Parts – Material

1) Body – Mild Steel

2) End Connector-Mild Steel

3) Ball-SS410

4) Stem – SS410

5) Body Seat – PTFE

6) Body Seal – PTFE

Parts – Material

7) Stem Packing – GFT

8) Gland – SS410

9) Gland Packing – PTFE

10) Body Stud/Nuts – B7/2H

11) Lever – Carbon Steel

12) Gland/Lever Nut – Carbon Steel

Ball Valve - Two Piece

(50mm to 150mm)

Standards : Steel Ball Valves API608 / API6D / BS53.51

Face to Face : ANSI B 16.10

End Drilled : ANSI B 16.5

Inspection & Testing : API 598/ API 6D / BS 5146

Body / Side Piece : ASTM A 216 GR. WCB

Ball : AISI 304 / 316 / 304L / 316L

Stem : AISI 304/316/304L/316L

Seat /Body/ Gland Seal : PTFE / Glass Filled PTFE

Stud & Nut: CS SS 304 /316

Handle : C.S

Sleeve : PVC

Testing standard : API 598 / API 60 / BS 5146

Hydro Shell : 30kg / sq.cm

Butterfly Valve Replicable Seat Design

Complies to BS EN 593, API 609

Sizes : 50mm to 300mm

Rating : PN 10/PN 16

Body Materials : CI, DI, WCB, CF8, CF8M, Even Rubber Lined

Discs : CI, DI, WCB, CF8, CF8M, Even Rubber Lined

Seats : Natural & Synthetic Rubbers

Ends : Wafer & Lugged

Operation : Hand Lever / Gear Box / Actuators

Butterfly Valve Bonded Seat Design

Complies to BS EN 593, API 609

Sizes : 50mm to 300mm

Rating : PN 6 to PN 16

Body Materials : CI, DI, WCB, CF8, CF8M, Even Rubber Lined

Discs : CI, DI, WCB, CF8, CF8M, Even Rubber Lined

Stem : SS410, 17-4PH & Monel

Ends : Wafer & Lugged

Operation : Hand Lever / Gear Box / Actuators

Right Angle Valve

Complies to BS EN 593, API 609 I

Manufacturing Std : ASME B16.34

Sizes : 6×6″/ 8″x8″/ 10″x10″/ 12″x12″ (Internal & External)

Inspection & Testing Std : API-598

Salient Features :

Bolted Bonnet, Outside Screw, Yoke type & Rising stem with Backseat arrangement, Handle operated, Straight pattern, Manufacturing Standard ASME B16.34

Test Pressure : (Hydraulic) Seat : 12 kg / sq.cm, Shell : 32kg / sq.cm

| Part Name | Materials | Specifications |

| Body, Yoke Disc | Cast Steel | ASTM A216 GR WCB |

| Stud | Alloy Steel | ASTM A193 GR.B7 |

| Nuts | Alloy Steel | ASTM A194 GR.2H |

| Valve Seat, Stem | Steam Joint Steel | AISI410 |

| Gasket | Spiral wound Gasket Graphite Filled | BS 3381 |

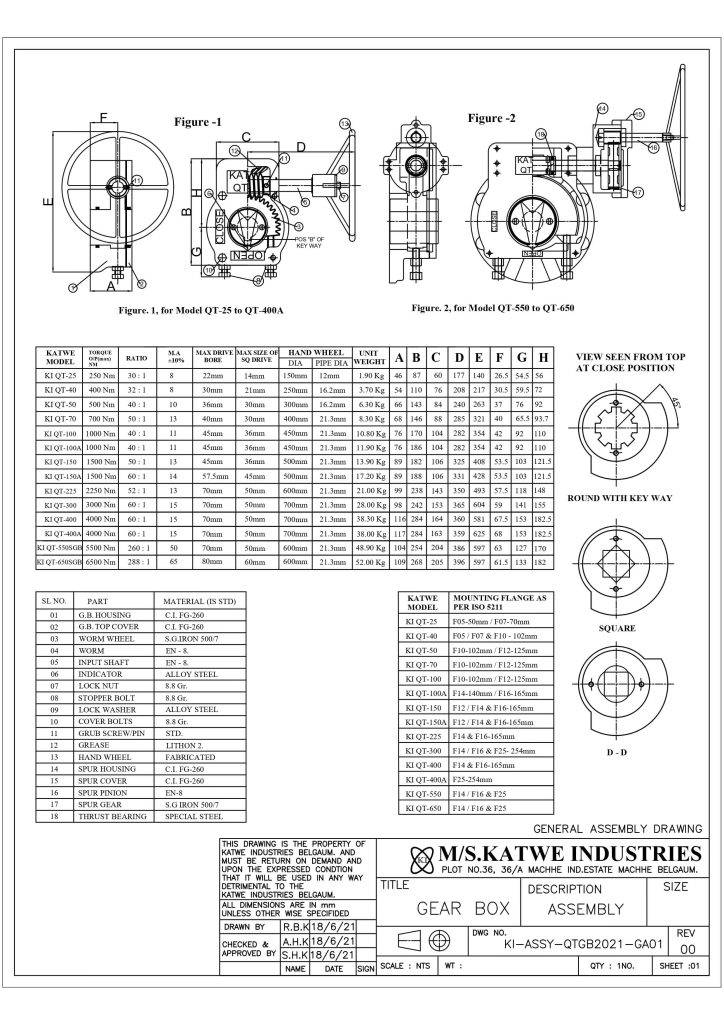

Quarter-Turn Gear Box

| SL NO | PART | MATERIAL | |||

| 1 | G.B. HOUSING | C.I. FG-260 | |||

| 2 | G.B. TOP COVER | C.I. FG-260 | |||

| 3 | WORM WHEEL | S.G.IRON 500/7 | |||

| 4 | WORM WHEEL | EN – 8. | |||

| 5 | INPUT SHAFT | EN – 8. | |||

| 6 | INDICATOR | ALLOY STEEL. | |||

| 7 | LOCK NUT | 8.8 Gr. | |||

| 8 | STOPPER BOLT | 8.8 Gr. | |||

| 9 | LOCK WASHER | ALLOY STEEL. | |||

| 10 | COVER BOLT | 8.8 Gr. | |||

| 11 | GRUB SCREW/PIN | STD. | |||

| 12 | GREASE | LITHON 2. | |||

| 13 | HAND WHEEL | FABRICATED. | |||

| 14 | SPUR HOUSING | C.I. FG-260 | |||

| 15 | SPUR COVER | C.I. FG-260 | |||

| 16 | SPUR PINION | EN-8 | |||

| 17 | SPUR GEAR | S.G IRON 500/7 | |||

| 18 | THRUST BEARING | SPECIAL STEEL | |||

| KATWE MODEL | TORQUE O/P(max) NM | RATIO | PERFORMANCE FACTOR 10% | MAX DRIVE BORE | HAND WHEEL DIA | UNIT WEIGTH | MOUNTING FLANGE AS PER ISO 5211 | ||

| KI QT-25 | 250 Nm | 30:1 | 8 | 22mm | 150mm | 1.90Kg | F05-50mm / F07-70mm | ||

| KI QT-40 | 400 Nm | 32:1 | 8 | 30mm | 250mm | 3.70Kg | F05-50mm / F07-70mm / F10-102mm | ||

| KI QT-50 | 500 Nm | 40:1 | 10 | 36mm | 300mm | 6.30Kg | F10-102mm / F12-125mm | ||

| KI QT-70 | 700 Nm | 50:1 | 13 | 40mm | 400mm | 8.30Kg | F10-102mm / F12-125mm | ||

| KI QT-100 | 1000 Nm | 40:1 | 11 | 45mm | 450mm | 10.80Kg | F10-102mm / F12-125mm | ||

| KI QT-100A | 1000 Nm | 40:1 | 11 | 45mm | 450mm | 11.90Kg | F14-140mm / F16-165mm | ||

| KI QT-150 | 1500 Nm | 50:1 | 13 | 45mm | 500mm | 13.90Kg | F14-140mm / F16-165mm | ||

| KI QT-150A | 1500 Nm | 60:1 | 14 | 57.5mm | 500mm | 17.20Kg | F14-140mm / F16-165mm | ||

| KI QT-225 | 2250 Nm | 52:1 | 13 | 70mm | 600mm | 21.00Kg | F14-140mm / F16-165mm | ||

| KI QT-300 | 3000 Nm | 60:1 | 15 | 70mm | 700mm | 28.00Kg | F14-140mm / F16-165mm / F25-254mm | ||

| KI QT-400 | 4000 Nm | 60:1 | 15 | 70mm | 700mm | 38.30Kg | F14-140mm / F16-165mm | ||

| KI QT-400A | 4000 Nm | 60:1 | 15 | 70mm | 700mm | 40.00Kg | F25-254mm | ||

| KI QT-550 | 5500 Nm | 260:1 | 50 | 70mm | 600mm | 45.90Kg | F14-140mm / F16-165mm | ||

| KI QT-550A | 5500 Nm | 260:1 | 50 | 70mm | 600mm | 48.90Kg | F25-254mm | ||

| KI QT-650 | 6500 Nm | 288:1 | 65 | 80mm | 600mm | 52.00Kg | F14-140mm / F16-165mm | ||

| KI QT-650A | 6500 Nm | 288:1 | 65 | 80mm | 600mm | 55.00Kg | F25-254mm | ||

| A | B | C | D | E | F | G | H | RATIO |

| 46 | 87 | 60 | 177 | 140 | 26.5 | 54.5 | 56 | 30:1 |

| 54 | 110 | 76 | 208 | 217 | 30.5 | 59.5 | 72 | 32:1 |

| 66 | 143 | 84 | 240 | 263 | 37 | 76 | 92 | 40:1 |

| 68 | 146 | 88 | 285 | 321 | 40 | 65.5 | 93.7 | 50:1 |

| 76 | 170 | 104 | 282 | 354 | 42 | 92 | 110 | 40:1 |

| 76 | 186 | 104 | 282 | 354 | 42 | 92 | 110 | 40:1 |

| 89 | 182 | 106 | 325 | 408 | 53.5 | 103 | 121.5 | 50:1 |

| 89 | 188 | 106 | 331 | 428 | 53.5 | 118 | 121.5 | 60:1 |

| 99 | 238 | 143 | 350 | 493 | 57.5 | 118 | 148 | 52:1 |

| 98 | 242 | 153 | 365 | 604 | 59 | 141 | 155 | 60:1 |

| 116 | 284 | 164 | 360 | 581 | 67.5 | 153 | 182.5 | 60:1 |

| 117 | 284 | 163 | 359 | 625 | 68 | 153 | 182.5 | 60:1 |

| 104 | 254 | 204 | 386 | 597 | 63 | 127 | 170 | 260:1 |

| 104 | 254 | 204 | 386 | 597 | 63 | 127 | 170 | 260:1 |

| 109 | 268 | 205 | 396 | 597 | 61.5 | 133 | 182 | 288:1 |

| 109 | 268 | 205 | 396 | 597 | 61.5 | 133 | 182 | 288:1 |

Knife Edge Gate Valve

Size Range: DN-50 To DN-600mm

Pressure Range: 150PSI PN-10 / PN-16

Type : Wafer or Lugged

| Part Name | Material |

| Body , Chest | Solid One piece casting of Cast Iron Fg 260 Cast Steel Gr WCB A-216 ,CF8,CF8M. |

| Seat | Integral to Body, Soft, Optional. |

| Gate | AISI SS 304,316 |

| Screw Spindle | AISI SS 410,304,316. |

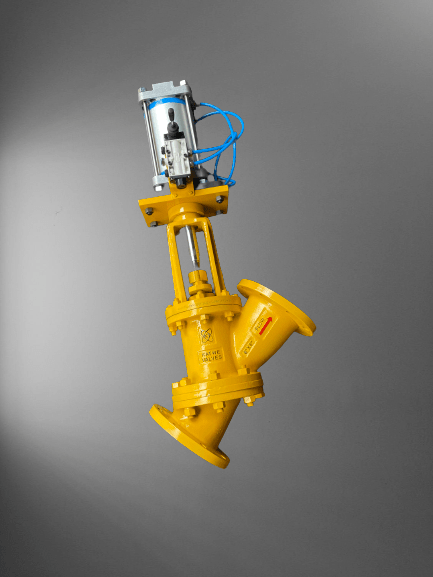

In-Line Angle Valve

Complies to BS EN 593, API 609

Manufacturing Std : ASME B 16.34

Sizes : 4″x4″ / 6″x6″ / 8″ x 8″ (Internal)

Inspection & Testing Std : API-598

Salient Features :

*Bolted Bonnet *Outside Screw *Yoke for stem movement *Pneumatically Operated *”Y”Type Pattern.

Manufacturing Standard: ASME B16.34

Test Pressure: (Hydraulic) * Seat : 10 kg / cm2 * Shell : 32kg/cm2

| Part Name | Material | Specifications |

| Body, Yoke, Disc | Cast Steel | ASTM A216 GR WCB |

| Stud | Alloy Steel | ASTM A193 GR.B7 |

| Nuts | Alloy Steel | ASTM A194 GR.2H |

| Valve Seat, Stem | Steam Joint Steel | AISI410 |

| Gasket | Spiral wound Gasket Graphite Filled | BS 3381 |